Ellis Band Saws

Stainless Steel

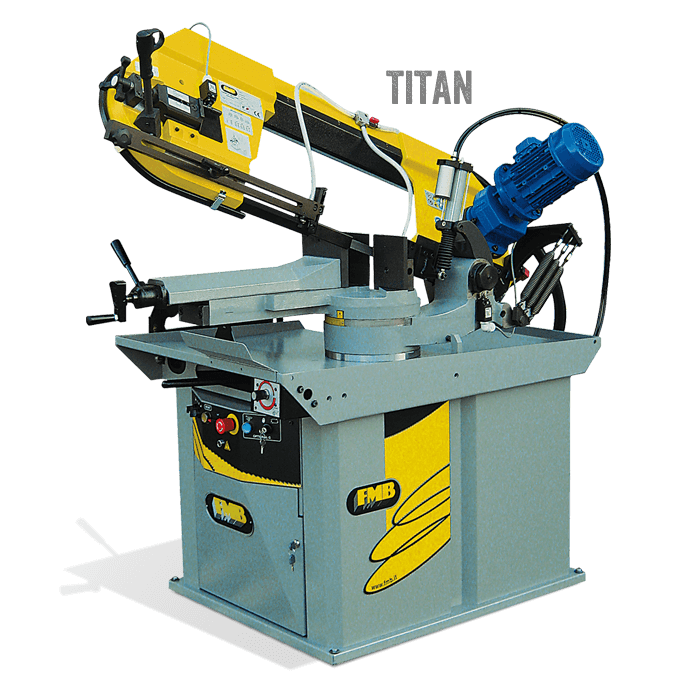

We have over 55 models of Manual Band Saws in stock. These models will be superior to any others currently on the market. It can be used for single or double mitering and has clamp vises, carbide drives and direct drives. This will allow you to get the highest metal fabrication outputs every day.

This bandsaw weighs in at over 300 lbs and is made with high-quality tubular steel.